Bearing Steels are special class of low alloy steels, typically with 1% Carbon and 1.4% Chromium. In special cases, Manganese and Molybdenum are also added. These steels find applications in automobiles, railways, earth moving, defense, aircraft, power generations, compressors, and other moving machinery parts. In view of the continuous fatigue strain during service, this steel and its components demand a high level of process discipline during manufacturing.

The components for these applications are manufactured either through hot forging route or through Spheroidized annealing followed by cold forging route. At Sunflag, all the necessary facilities for manufacturing and testing of bearing steel grades have been established. Various controls are exercised during manufacturing, right from selection of raw materials and ferro alloys required to meet the stringent quality parameter of the various customer.

- Fatigue Life

- Uniform heat treatment response

- Compact Structure with uniform grain flow and fine grain size

imparting high impact toughness

Inspection activities before dispatch are designed to address the verification of all the quality requirements of bearing steels. Any deviation observed during production process and quality testing is recorded and analysed for taking suitable corrective and preventive actions to meet the quality requirements of this critical Steel grade.

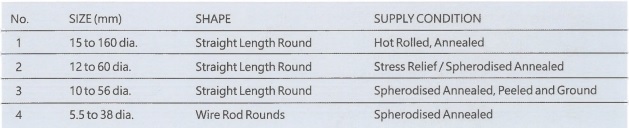

Size and Condition of Supply

| No. | Size(mm) | Shape | Supply Condition |

| 1 | 15 to 160 dia. | Straight Length Round | Hot Rolled, Annealed |

| 2 | 12 to 60 dia. | Straight Length Round | Stress Rehef/Spherodlsed Annealed |

| 3 | 10 to 56 dia. | Straight Length Round | Spherodised Annealed,Peeled and Gmund |

| 4 | 5.5m to 38 dia. | Wire Rod Rounds | Spherodised Annealed. |

More shapes sizes with a combination of different supply condition can be developed as per specific requirement by customers

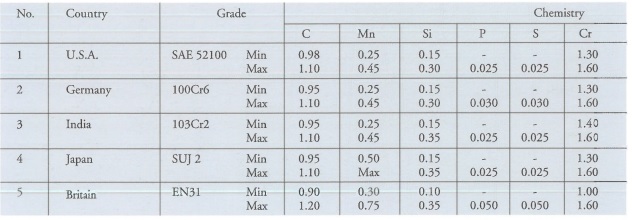

International Specifications Of Ball Bearing Steels

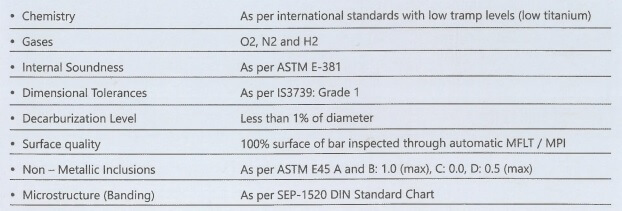

Certification of Quality

Following important quality features are tested and certified on all Bearing heats made at Sunflag.

| Chemistry | As per international standards with low tramp levels (low titanium) |

| Gas | 02, N2 and H2 |

| Internal Soundness | As per ASTM E-381. |

| Dimensional Tolerances | As per IS 3739: Grade 1 |

| Decarburization Level | Less than 1% of diameter. |

| Surface quality | 100% surface of bar inspected through automatic MFLT / MPI |

| Non — Metallic Inclusions | As per ASTM E45 A and B: 1.0 (max), C: 0.0, D: 0.5 (max) |

| Microstructure (Banding) | As per SEP-1520 DIN Standard Chart |

Any other special testing requirement found desirable by the customer can be satisfied.

Bearing steels are special class of low alloy steels, typically with 1% carbon and 1.4% chromium. Manganese and Molybdenum are added in certain special cases.