Microalloyed Steels

Introduction

The use of MICRO ALLOYED STEELS (MAS) originally developed for high strength low alloysteel sheets (HSLA) for automobile bodies has shown steady and significant growth in Long products also for manufacture of forged components. The Indian steel manufacturers as well as forged components manufacturers have adapted themselves to manufacture and use MAS components for AUTO sector.

MAS grades not only helps in avoiding use of costly alloying elements but also eliminates the need for heat treatment of forged components. Plain carbon steels having closely controlled chemistry (to maintain Carbon Equivalent) alongwith small additions of microalloying elements such as V, Nb and Ti (to promote Precipitation Strengthening) can achieve the desired strength levels after forging without heat treatment. Optimum Sulphur levels and maintained to promote machinability.

These steels are covered by EN spec10267 as general spec, which can be fine tuned to meet specific customer requirements.

Sunflag melting and refining process has capability to meet close range chemistry with help of controlled addition of Microalloying Elements like V, Nb, Ti and special wire injection facilities for sulphur and aluminium addition.

Nitrogen can also be closely maintained in the range of 100 to 200 ppm as specified by customer.

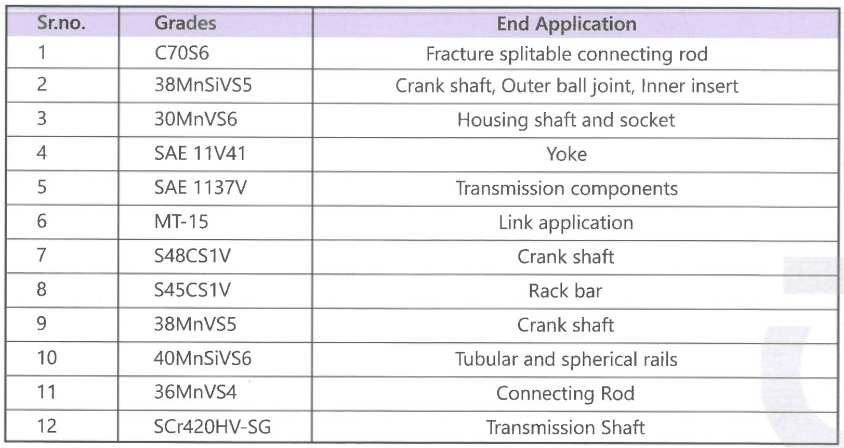

Microalloyed Grades Being Produced

| Sr.no. | Grades | End Application |

| 1 | C70S6 | Fracture splitable connecting rod |

| 2 | 38MnSiVS5 | Crank shaft, Outer ball joint, inner insert |

| 3 | 30MnVS6 | Housing shaft and socket |

| 4 | SAE 11V41 | Yoke |

| 5 | SAE 1137V | Transmission components |

| 6 | MT-15 | Link application |

| 7 | S48CS1V | Crank shaft |

| 8 | S45CS1V | Rack bar |

| 9 | 38MnVS5 | Crank shaft |

| 10 | 40MnSiVS6 | Tubular and spherical rails |

| 11 | 36MnVS4 | Connecting Rod |

| 12 | SCr420HV-SG | Transmission Shaft |

Bearing steels are special class of low alloy steels, typically with 1% carbon and 1.4% chromium. Manganese and Molybdenum are added in certain special cases.