Edge Radius

Flats can be supplied with an edge radius “R” which is equal to either “T’ or “T/2″, where “T” is equal to thickness.

General Length

We cater to orders in standard and specific length:

-

- a)Standard length 4 to 6 mtrs with 10% shorts down to 1 mtr.

-

- b) Customer’s specific lengths with tolerance + 50/-Omm.

Straightness

Bars hot rolled 3 mm/mtr (max) & hot rolled & machine straightened 1 mm/mtr (max)

Quality

Surface Condition: On visual inspection, surface is free from harmful defects, eg. Crack, lap, fold, scratch, roll/pass marks, pits etc.

SIZES AND CONDITIONS OF SUPPLY

| Condition of Supply | Shapes | Sizes |

| Hot Rolled | Flat(W*T) | 50*5 mm-125*34 mm |

| Hot Rolled | Round | 5.5 to 250 mm |

| Drawn | Round | 5-50 mm |

| Peeled and Ground | Round | 5-100 mm |

Decarburization

| Decarburization | Full | Partial | Total |

| Flats (upto 80*13) | Nil | 0.15 | 0.15 mm (max) |

| Flats (above 80*13) | 0.03 | 0.25 | 0.25 mm (max) |

| Hot Rolled Round | – | 0.8% | 0.8% of the size (max) |

Grain Size

5.8 (As per ASTME-112)

As Rolled Hardness

310 BHN (max)

Inclusion Rating

As per IS-4163/ASTME-45 :THIN: 2.5 A, B, C, D max

HEAVY : 1.5 A, B, C, D Max

As per JIS G-0555 : % dA – 0.15 max

% dB + dC – 0.10 max

% d Tot – 0.20 max

Delivery Conditions

All bundles tied with wire/strapping at 3/4 places.

Approx. bundle weight : 2 MT. max

Grade/HT. No. identification : By painted colour code and Heat Number written on each bundle / bar

Standard shapes and sizes of Spring Steel Flat Bars

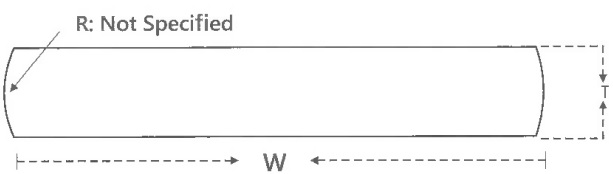

1. RE Type

The conventional type is of Round Edge (RE) type, having edge radius approximately equivalent to thickness but not specified.

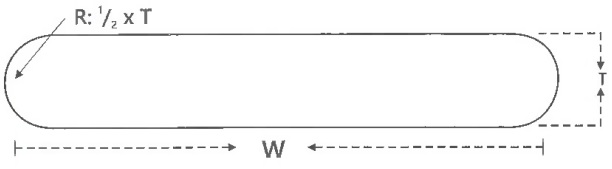

2. FL Type

Feather leaf type Spring Steel flats have edge radius of half of thickness and also have many advantages over RE type in terms of economical and technical aspects. Size – wise edge radius is be mutually agreed.

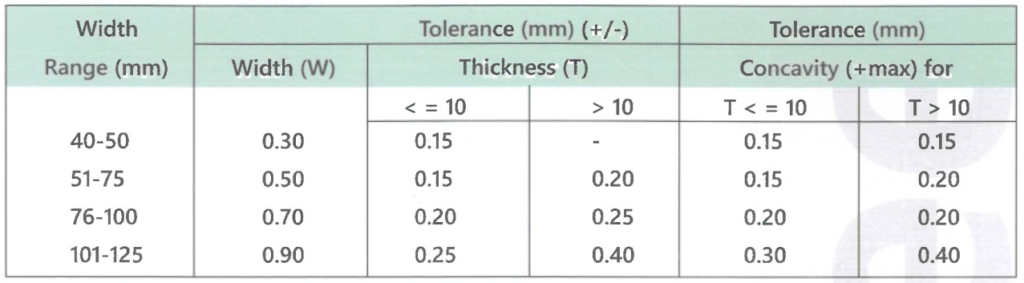

DIMENSIONAL TOLERANCES

Flats:

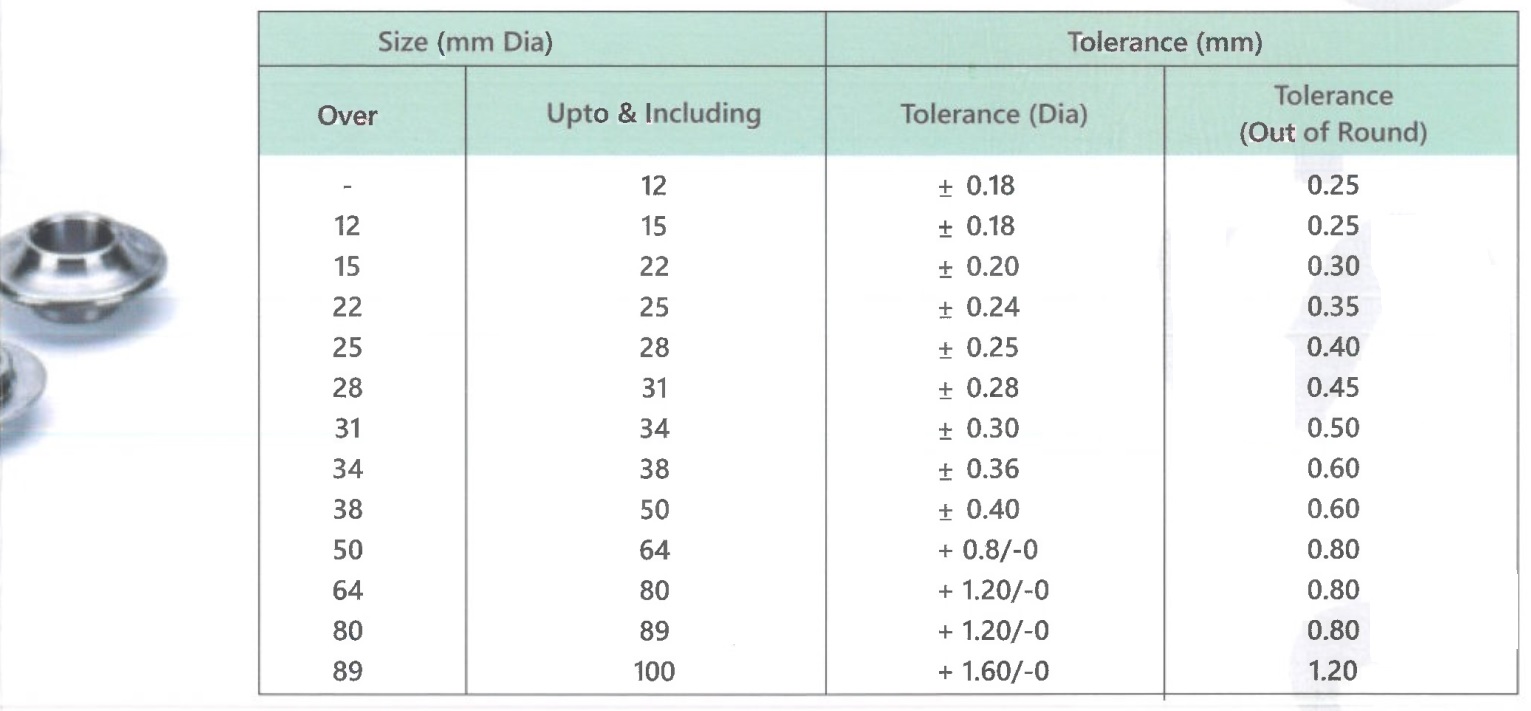

ROUNDS (HOT ROLLED)

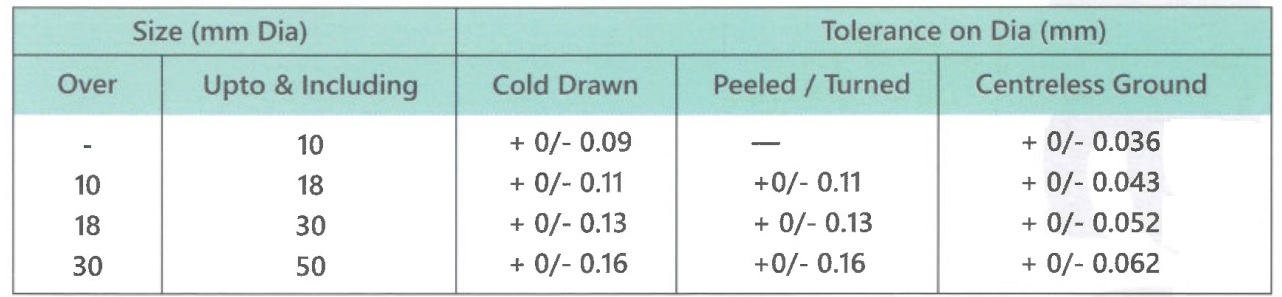

ROUNDS (BRIGHT BARS)

FATIGUE GUARANTEED SPRING STEELS

Sunflag Steel, a pioneer in making Spring Steel, has come up with products in this category, which ensure the required fatique life to springs used in vehicles, in the most demanding situations.

THE SALIENT FEATURES OF THESE PRODUCTS ARE :

- Use of virgin inputs in steel making such as DRI, Pig Iron which are free from undesirable tramp elements.

- Carefully planned, steel making refining vacuum degassing and casting processes.

. - Well controlled reheating and rolling process.

- Closely monitored cooling parameters of rolled products.

- Thorough inspection and testing.

- Proper packing, stacking and storage for despatch.

- Wide size range.

CHEMICAL COMPOSITION OF TYPICAL

SPRING STEEL OF VARIOUS INTERNATIONAL STANDARDS

Spring steel is used for manufacturing various types of springs and components, for the suspension mechanism in Automobiles and railways.