Previous

Next

R & D division of Sunflag Iron Steel Co. Ltd. Plays a pivotal role in retaining and consolidating Sunflags‘ leadership position in automobile industry. R & D focus on development of new steel grades, process improvement, continous Lip-gradation of Quality, Customer Satisfaction through customized products matching with their specific requirement.

Sunflag R&D lab is equipped with following state of the art equipment:

- Scanning Electron Microscope with Energy Dispersive X—Ray Spectroscope (SEM—EDS) of Make — JOEL

- Immersion Ultrasonic Testing Facility of Make — Olympus / Blue Star

- Optical Microscope with Automatic Multiaxis stage Movement and Image Analysis software

- Micro—hardness tester

- Ferritometer

- NABL Certified Testing Lab

- R & D Centre Recognised DSIR Government of India

SCANNING ELECTRON

MICROSCOPE WITH EDS

- Key Function

– Microstructure analysis

– Quantitative 8L qualitative Analysis of Inclusions

- Failure Analysis

- Fractography

- Inclusion with quantitative elemental analysis

Salient Features

- Fully automatic system comprising of Turbo molecular rotary pump

- Automatic stage movement

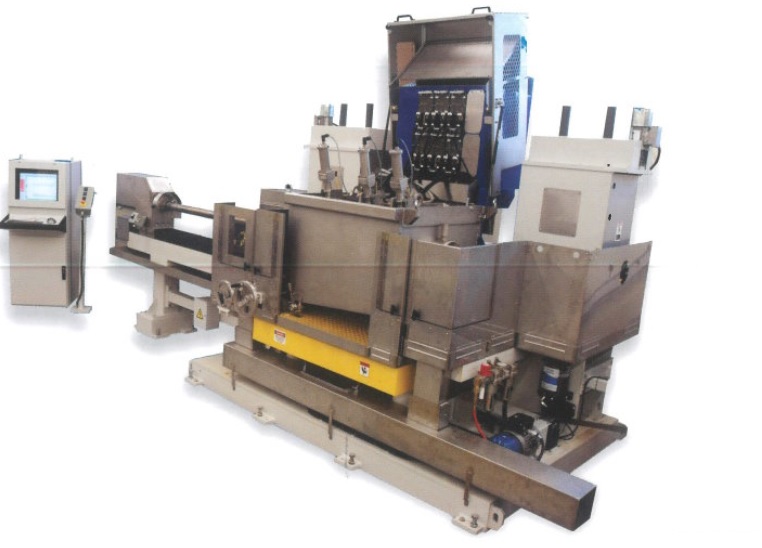

IMMERSION ULTRASONIC

TESTING MACHINE

- Key Function: Inspection of cleanlinesslevels (macro inclusions) in steel

Salient Features.

- Dimension of samples that can be tested :

– Round Bars :

- Size 15-120 mm die.

- Length 800mm

- Round Corner Square Bars:

- Size 60420 mm

UST Prob: 10 MHz — 6mm as per Sep1927

- Automatic data saving 8L reporting

- A scan 8L C scan analysis with real time display

Quality Highlights

Inclusion Mapping with 100% volume as Sep 1927 Class I to 5

UPRIGHT METALLURGICAL MICROSCOPE

WITH CLEMEX SOFTWARE

- Automatic Motorised Stage & Auto Focus

- Clemex Automated Inclusion Rating Analysis As per

– ASTME 45 Method A, C, D, E

– Din 50602 Method K, M,

– JlS G 0555,

– ISO 4967 compliant (DS)

– EN 10247 Complete analysis by all above

methods simultaneously

- Automated Grain Size measurement

- Phase analysis

AUTOMATIC MAGNETIC FLUX LEAKAGE TESTING (MFLT)

- Highly sensitive test method for detection of longitudinal defects on steel bars

- No Coupling Liquid

- Reliable and reproducible test results

- Automatic marking and sorting of defective bars during testing

- High production speed

- Real time display of inspection results

MFLT SALIENT FEATURES

| Diameter Range | 5 to 140 mm |

| Channels | 8 |

| Probes | up to 16 |

| Channel Width | 5.0 mm |

| AC Frequency | 7 KHz |

| Rotation | max.1.800 rpm |

| Test Speed | up to 2 m/s for 100% Material Scanning |

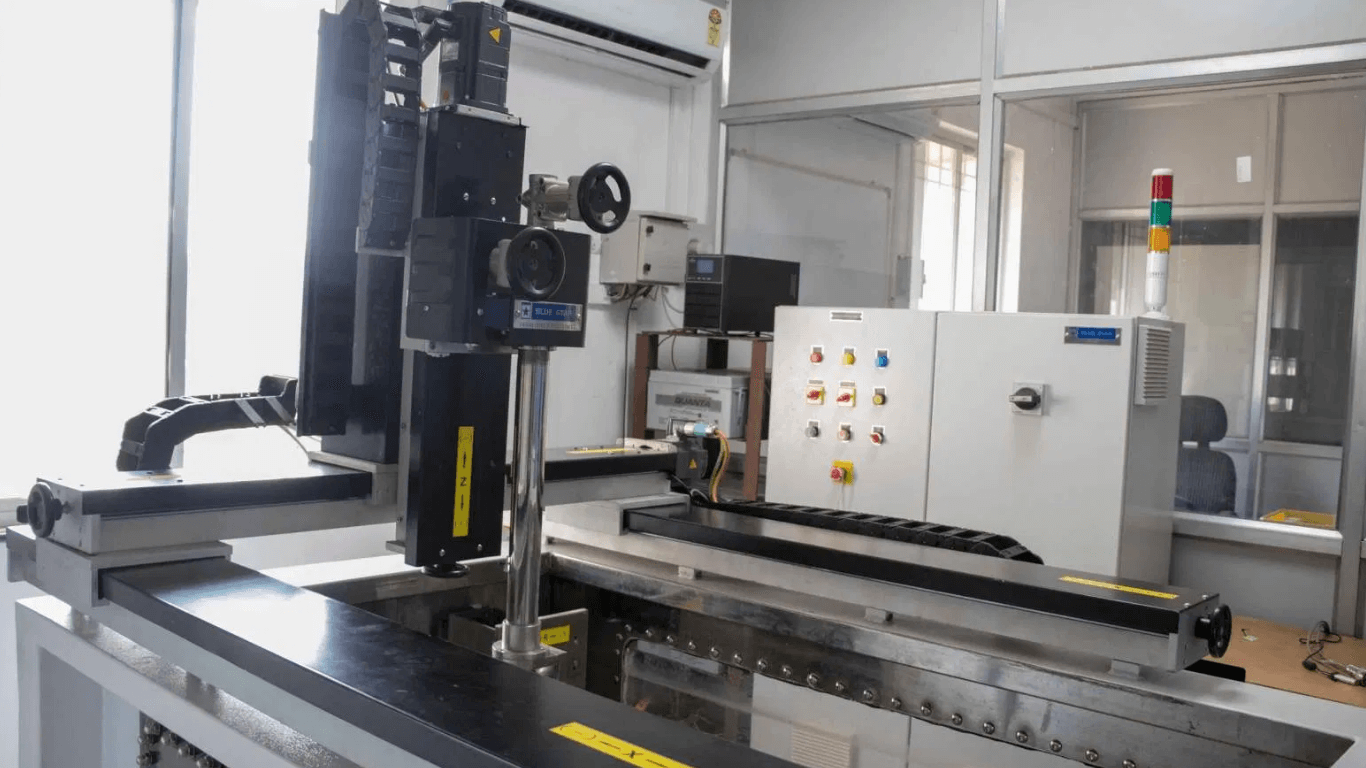

AUTOMATIC EDDY CURRENT TESTING (ECT)

FOR BAR & WIRE RODS

ECT is a non-destructive testing technique making use of electromagnetic induction to detect and

characterize surface 8L subsurface flaws for bright bars.

SALIENT FEATURES

ECT For Bars

- Automatic bar feeding system

- Automatic marking and sorting of defective bars during testing

- Size range: 6 to 60 mm

- Inspection of Longitudinal / Circular Surface defects

- Detectability of ECT: 0.05mm depth flaw with length 5mm I Detectability of ECT: 0.05mm depth flaw with length 5mm

- Reliable and reproducible test results I Reliable and reproducible test results

- High production speed

ECT For Bars

- Automatic bar feeding system

- Automatic marking and sorting of defective bars during testing

- Size range: 6 to 60 mm

- Inspection of Longitudinal / Circular Surface defects

- Detectability of ECT: 0.05mm depth flaw with length 5mm I Detectability of ECT: 0.05mm depth flaw with length 5mm

- Reliable and reproducible test results I Reliable and reproducible test results

- High production speed

PHASED ARRAY AUTO ULTRASONIC TESTING

SALIENT FEATURES

Phased Array Technology

Phased Array testing is a specialized type of ultrasonic testing that uses sophisticated multi- element array transducers and powerful instrumentation/software to steer ultrasonic beams through the test piece and map returning echoes.

No rotating movement, only electronic scanning is done:

Depth focalization for bar volume inspection (LW)

Electronic steering for bar surface inspection (SW)

Quality Highlights:

Capacity — 15 to 120 mm dia. Full bar volume inspection

Acceptance Criteria

Minimum defect depth and length (FBH)

- 0.7 mm FBH from 15—60 mm dia

- 1.2 mm FBH above 60 dia

Minimum defect depth and length (SDH)

- 0.5 mm x 10 mm {from 15—120 mm dia)

- 0.3 mm SDH sensitivity can deduced by

extrapolation depending material SNR.