Applications

End Application Of Steel Grades Produced At Sunflag

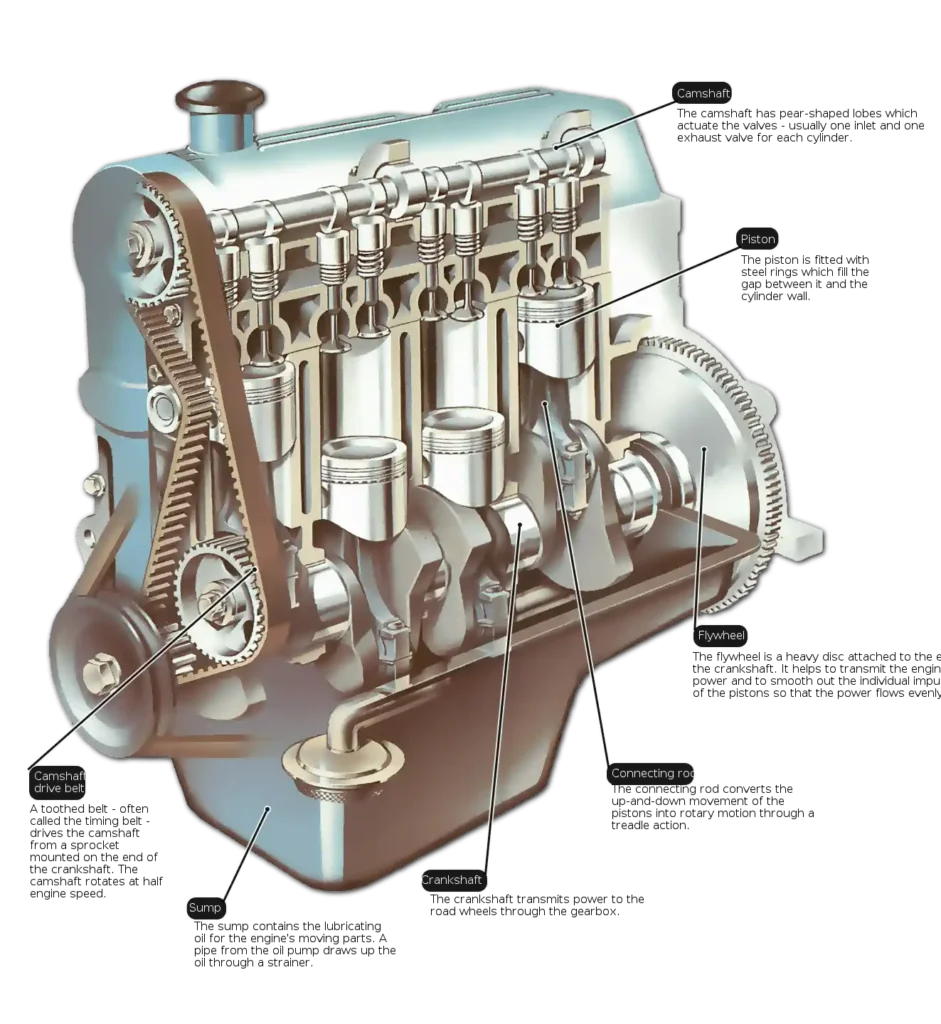

Engine / Motor Parts:

Connecting Rod

—SCM 420 H, SCR420H, S35C, S48C, C70S6, 42Cr4Mo2

Camshaft

—EN207, 45C8

Rocker Arm & Shaft

—SCr 420H, SCM 420H

Crank Shaft

—HS20CMS1, S30CMS1, 38MnSiV5/6, S48CS1V, 41Cr4, SCM435, S48C

Crank Pin

—SCM420H2V2

Piston Pin Steel Grades

—15Cr3, 17Cr3, 15CrNi6, EN 353, 16MnCr5, SCM420, SAE8620

Valve Steel Grades

—21-4N, EN 52

CRDI (Common Rail Distribution Injection) system – Fuel Injector Nozzle Body

—C45PbHHK

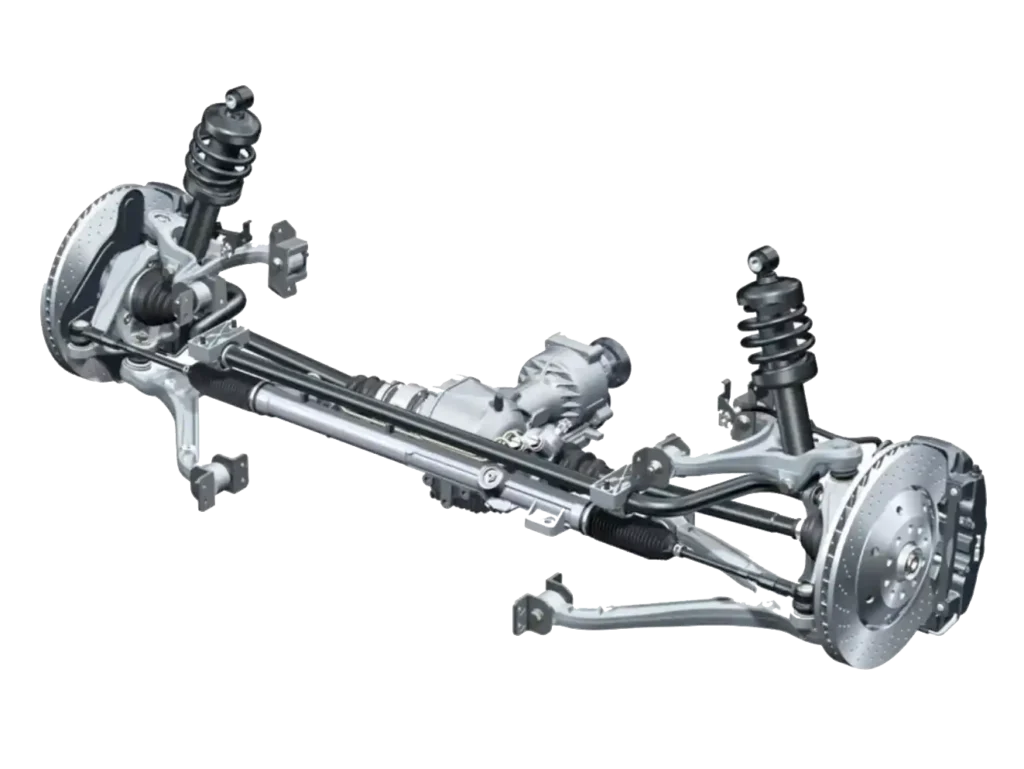

Drive Trains – Steering Systems:

Rack & Pinion System Steel Grades

—SCM 415H, SCM 420 HV, S45C H&T, S45CS1V, S45CS1 H&T

Front Axle Beam & RA Shaft

—40Cr4C

Stub Axle Steel Grades

—40Cr4B, 20MnCr5(B)

Steel for Drives

—Tulips & Cups : SAE 1050/XC45/ CF53

—Drive Shaft : 15B41/ 38B3/Ck45

—Spider:18CD4

—Cage: SAE8617/16MnCr5/20MnCr5

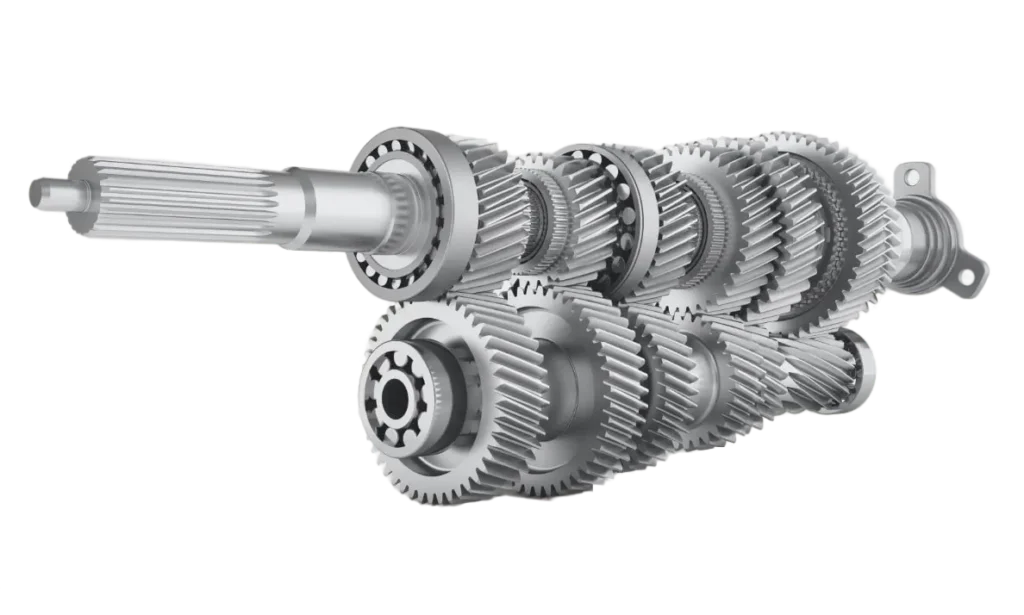

Transmissions & Gear Boxes

Gear Steel

—SCM 415 H/ 420 H, SCr 415 H / 420 H, 20MnCr5 / 16MnCr5, SAE 8620H / EN353

UJ CROSS Steel Grades

—20MnCr5, EN 353

Axle Shaft Steel Grades

—SAE 15B41H, SAE 1038, S53C, 40Cr4C/B

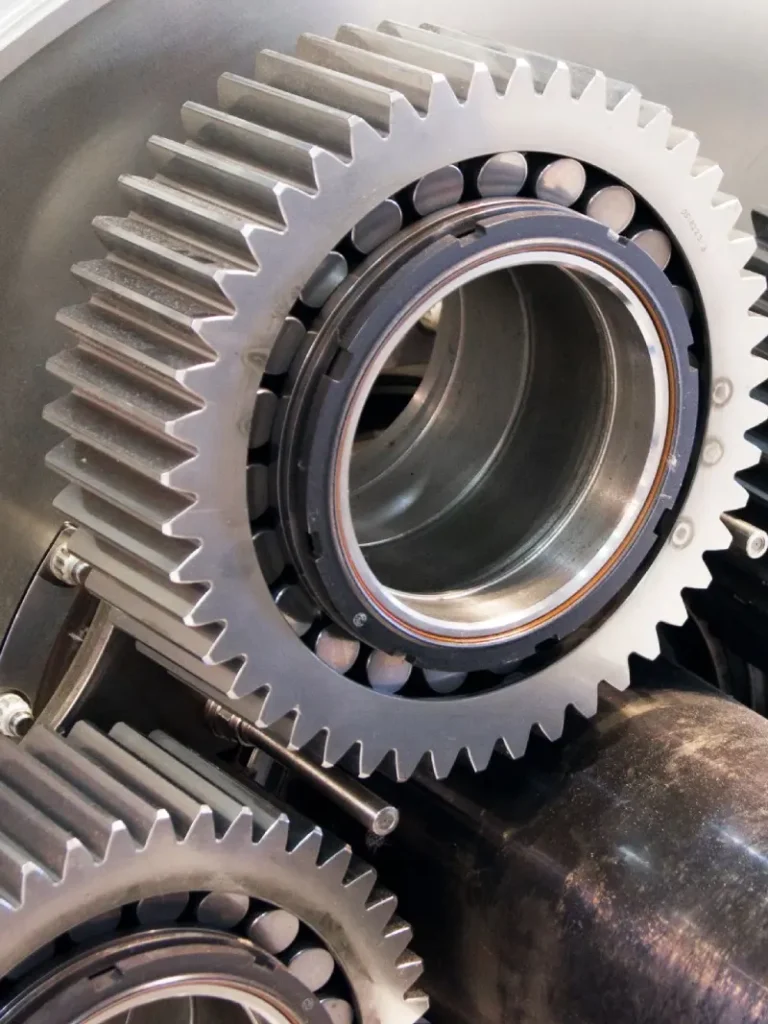

Bearing Steel grades

—100Cr6/SAE 52100/SUJ 2

Suspension Systems

Coil Springs

—SAE 9254/SUP12V/SUP7NV

Stabilizer Bars/ Leaf Springs

—SAE 5160/SUP9