With different types of steel out there, it is understandable that there would be confusion about what each one means. Not only are they vastly different in their uses and durability, they are also made in different ways with very different components. Knowing what components different steel is made with is a great way to determine how it is useful to your needs, and which one to choose. In this piece, we will look at the key differences between stainless steel and mild steel, in order to better understand them and their potential.

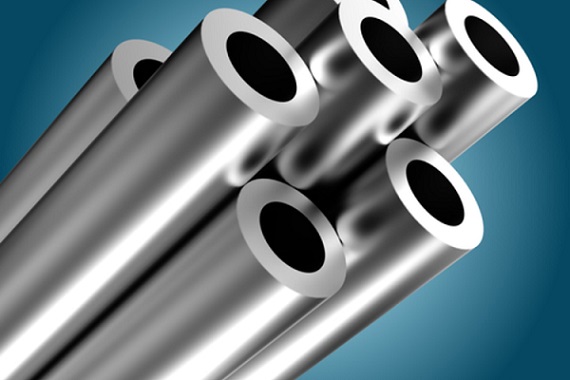

STAINLESS STEEL

Stainless steel is a steel alloy with a minimum chromium content of 11.5%. Unlike other steels, it is known for not corroding or rusting as easily. The chromium is what prevents it from staining – so, the higher the chromium, the more resistant it is to oxidizing. While not 100% rust proof, it is certainly much less likely to go through weather damage in comparison to regular steel.

MILD STEEL

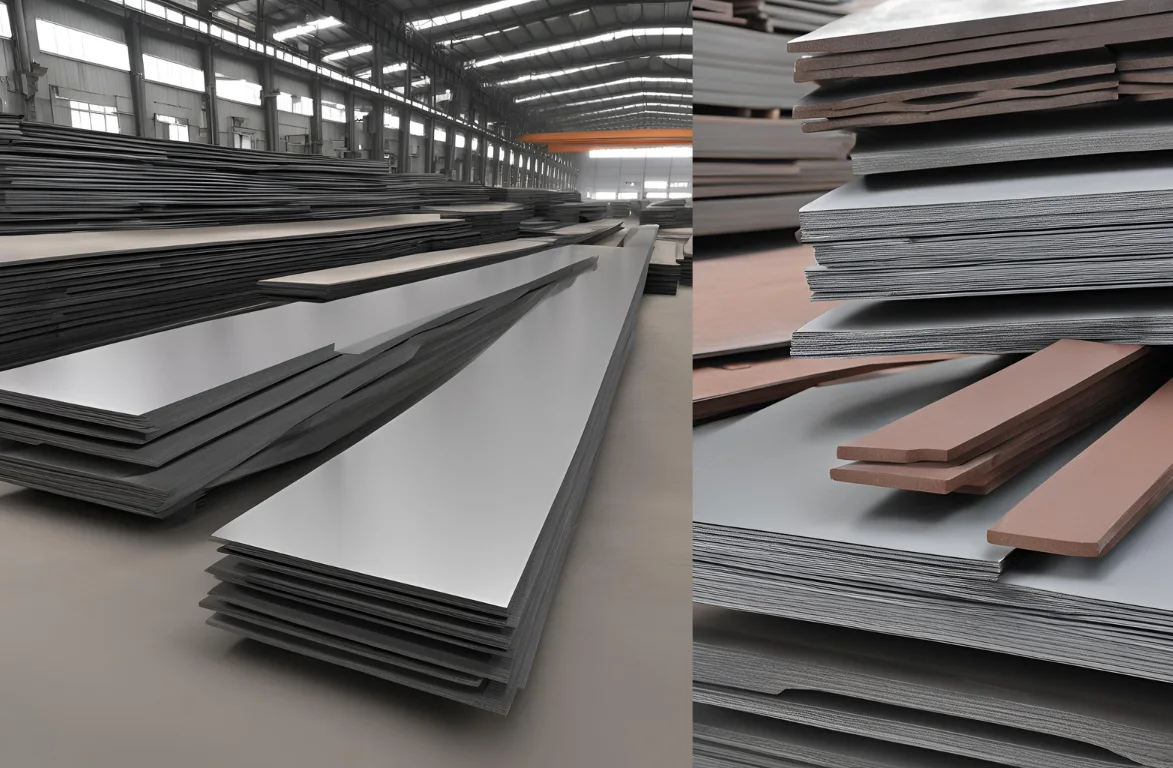

Mild steel is a form of steel alloy that is also called “plain carbon steel”. It is one of the most common forms of steel, which is used in a variety of manners – particularly in the transport and construction industries. Carbon steel with less than 0.5% of carbon is referred to as mild, or low carbon steel. In comparison to steel with high carbon content, this is far more ductile. It can be made into many shapes, from sheets to beams, depending on its use.

HOW ARE THEY DIFFERENT?

As the name suggests, stainless steel is more resistant to corrosion. Unlike mild steel, which needs to be galvanized to prevent corrosion, stainless steel merely requires polishing. This makes stainless steel highly sought after for uses that require aesthetic integrity. Examples include household items, as well as clothing and fashion industry (watch straps, belt buckles, shoe components). This is also because stainless steel is more lustrous in appearance to the dull, matte finish of mild steel. Stainless steel is also resistant to high impact because of the presence of chromium.

With different types of steel out there, it is understandable that there would be confusion about what each one means. Not only are they vastly different in their uses and durability, they are also made in different ways with very different components. Knowing what components different steel is made with is a great way to determine how it is useful to your needs, and which one to choose. In this piece, we will look at the key differences between stainless steel and mild steel, in order to better understand them and their potential.

STAINLESS STEEL

Stainless steel is a steel alloy with a minimum chromium content of 11.5%. Unlike other steels, it is known for not corroding or rusting as easily. The chromium is what prevents it from staining – so, the higher the chromium, the more resistant it is to oxidizing. While not 100% rust proof, it is certainly much less likely to go through weather damage in comparison to regular steel.

MILD STEEL

Mild steel is a form of steel alloy that is also called “plain carbon steel”. It is one of the most common forms of steel, which is used in a variety of manners – particularly in the transport and construction industries. Carbon steel with less than 0.5% of carbon is referred to as mild, or low carbon steel. In comparison to steel with high carbon content, this is far more ductile. It can be made into many shapes, from sheets to beams, depending on its use.

HOW ARE THEY DIFFERENT?

As the name suggests, stainless steel is more resistant to corrosion. Unlike mild steel, which needs to be galvanized to prevent corrosion, stainless steel merely requires polishing. This makes stainless steel highly sought after for uses that require aesthetic integrity. Examples include household items, as well as clothing and fashion industry (watch straps, belt buckles, shoe components). This is also because stainless steel is more lustrous in appearance to the dull, matte finish of mild steel. Stainless steel is also resistant to high impact because of the presence of chromium.

However, this makes it less malleable. Mild steel is easier to produce and shape depending on its usage. For this reason, it is used in construction and electronic industries. Its ability to be stretched into sheets, beams, wires makes it an attractive option for non-aesthetic and versatile uses. It is the most common steel with a high volume of production. In places where a large amount of steel is used, it is convenient and more cost-effective to opt for mild steel.

Stainless steel is also fairly harder compared to mild steel. This is because stainless steel is resistant to water based corrosion. Unfortunately, this makes stainless steel less ductile. It is a lot more difficult to weld, unlike mild steel. Of course, mild steel can be easily hardened by introducing more carbon into it if the need is present. However, it’s lower hardness makes it more attractive for large-scale work.

These properties also make mild steel much lighter than stainless steel – another factor which boosts its use in construction. Unless construction work requires resistance from corrosion (like in building cladding, where stainless steel is used), using mild steel for internal structures is easier. It is also convenient to transport in large quantities for this reason.

Another difference is the cost of production. Stainless steel’s components make it expensive to produce, unlike regular carbon steel. This is not just because of the cost of raw ingredients, but also the manufacturing process. There are more steps involved, and highly skilled workers are required to produce stainless steel. So, if money-saving is your goal, then opting for mild carbon steel is much better on the wallet compared to stainless steel.

Which type of steel you opt for is dependent on your specific needs. At Sunflag Steel, we value competitive pricing along with high quality production so that you get the right kind of product for the right uses. If you are unsure about which steel works best for you, then getting a consultation from knowledgeable engineers helps in understanding how the difference will make an impact on the finished product.