Steel fabrication is a process that is used to develop various components and products that we use in our day-to-day life. It’s a process of transforming raw steel into a product or an item that can be used in construction projects. This process involves taking raw materials and shaping them to the required form.

In this method, the raw materials are melted down and processed into finished steel product before being created into shapes. The steel fabrication process requires highly-skilled workers with experience in transforming raw components into marketable items.

The use of steel fabrication depends on the end-use of the product being fabricated. However, steel fabrication falls into three main categories-

- Commercial Fabrication: This fabrication process develops commercial products that are used by consumers. Appliances and cars, steel parts are the best examples of commercial fabrication.

- Industrial Fabrication: Industrial fabrication designs pieces that are used in developing other equipment. Bandsaws and ironworking machines are the best examples of industrial fabrication.

- Structural Fabrication: Structural fabrication refers to metalworking which is used as a part of the building process. Usually, structural fabricated steels are used in shops, manufacturers, buildings and skyscrapers.

PROCESS OF STEEL FABRICATION

Corrosion resistance, strength and durability are some of the principal characteristics of steel. The primary methods of fabricating steel include cutting, folding, welding, machining, shearing, punching, stamping and casting. Here is a brief overview of how each of these processes work:

- Cutting- It is the most commonly used steel fabrication process that involves splitting the metal sheet into halves, thirds or smaller sections. Mostly, the sheets or bars are being cut and recreated into other desired shapes. They are cut using lasers and plasma torches that make the end product a more elaborate and high-tech piece.

- Folding- Folding is one of the most complicated processes that involve the manipulation of steel into shapes of a certain angle. In this process, the metal surfaces are being folded at a 90-degree angle or other degrees to make the product more or less blunt.

- Welding- This process involves the joining of two separate metal parts. The parts used in this process include sheet, panels, bars or any other shaped steel. They are joined together through numerous methods and machines that result in finished usable products.

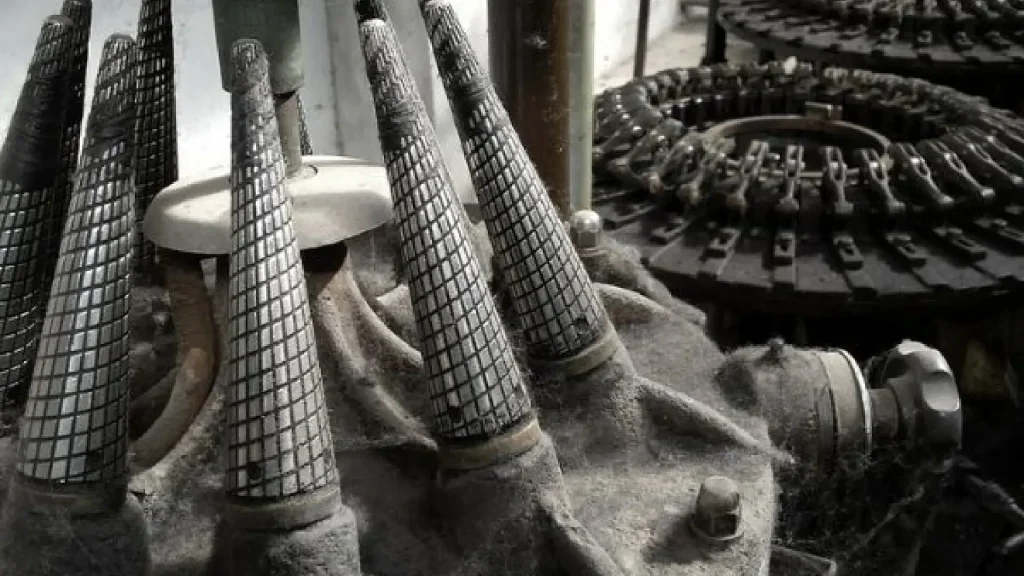

- Machining- Machining is a process of removing portions from a piece of metal. The process is usually performed on a lathe, which rotates the metal against tools that trim the corners and edges to cut the piece to the desired shape.

- Punching- Punching is the process of forming a hole in a metal piece, where metal is placed under a die and punched through by a drill. In most cases, the holes are drilled into a panel of metal to fasten the latches or other foreign parts. In other applications — also known as blanking — the area with the hole is precisely extracted from the larger panel to form a bit smaller part.

- Shearing- Shearing is a steel fabricating process that is used to cut straight lines on the flat steel sheet. During this process, a top blade and a bottom blade are driven past each other with the little space between them. Usually, one of the blades remains fixed. Steel shearing can be performed on a sheet, strip, bar, plate, and even angle metal stock.

- Stamping- It is a fabrication process used to transform flat steel sheets into particular shapes. It is a complicated process that can incorporate several metal forming techniques like blanking, punching, bending and piercing.

Stamping is similar to carving. A primary example of metal stamping is seen on coins, where words, currency, amounts etc. are stamped on each side of it. - Casting- Casting is a process in which hot liquid metal is poured into a mould that holds a hollow cut out of the desired shape. The liquid metal is then left to solidify, which is removed from the mould, revealing the end product, or the “Casting Form.” As one of the most flexible methods of metal fabrication, casting is ideal for a wide range of complex shape-making. The most common examples are jewellery, sculptures, weapons etc.

From paperclips to plane parts, steel is used to create a wide variety of products. It comes in several distinct grades and holds unique chemical compositions. At Sunflag Steel, we provide you with the best quality steel that is durable and sturdy in the long run.