Often projects involve the usage of concrete to create long-lasting construction results. Whether you are building walls, roads or other structures like bridges, pathways etc., you can consider using Rebar or Wire Mesh under your concrete structure. Using any of these supporters provides significant reinforcement and has a long-lasting effect. But before using that, it is quite necessary to understand the difference between Wire Mesh and Rebar. So let’s take a look at how these methods are a robust option to make your concrete projects durable.

WHAT IS WIRE MESH?

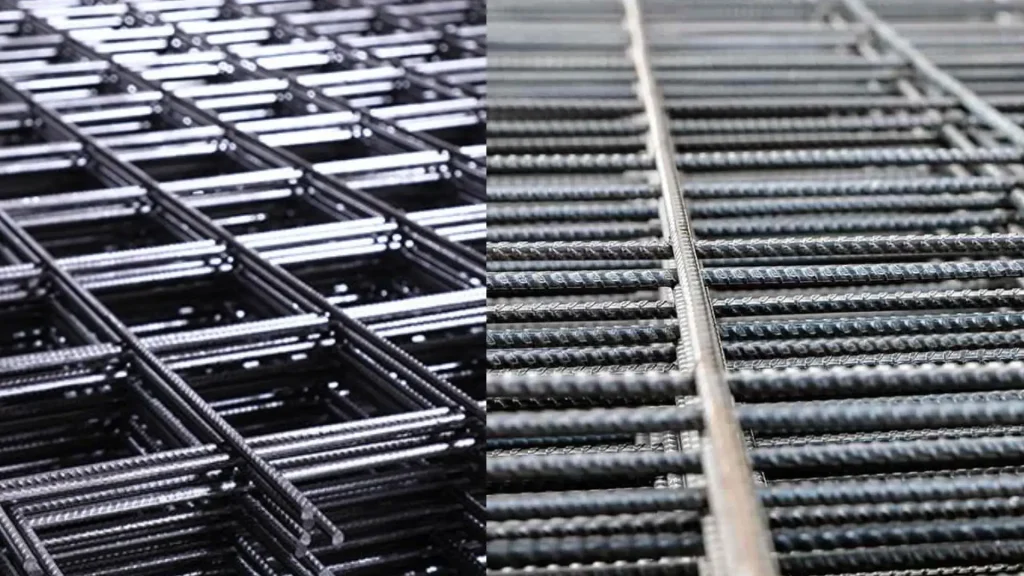

Wire Mesh, also known as wire cloth or wire fabric, is a highly versatile product that can be used in countless applications. Depending upon the manufacturing capabilities, wire mesh can be made with an endless combination of opening sizes and diameter wires, which is either woven or welded as per the requirements. They are woven metal fabric created in varying degrees of coarseness, weight, and aperture.

When using Wire Mesh for concrete, it gives a significant advantage that allows a certain amount of shaping of concrete which is not possible with Rebar. Wire mesh comes in various materials such as plain steel, galvanized, or stainless steel products that are resistant to corrosion, which is why it is convenient to use.

WHAT IS REBAR?

Rebar is a structured steel bar that is primarily used in concrete construction. With the help of these reinforcing steel bars, the reinforced concrete surface is prepared. They are often used on floor slabs, walls or posts. It helps keep cracks that protect the surface from falling apart. It also provides structural strength to the structure. When opting for Rebar, various grades and sizes of steel for whatever strength level are required.

HOW IS WIRE MESH AND REBAR MADE?

To make Wire Mesh, metal wires are woven on industrial weaving looms. They are made as per a precise specification, leaving either square or rectangular gaps between the wires. The wire mesh is created by weaving metal on automatic rapier-style looms that give precise control over the number of wires used to make the finished mesh. This closely regulates the approach that is required to maintain consistency in both aperture size and mesh thickness.

To make Rebar, steel (carbon or alloy) is melted down to liquid form. Once melted, the liquid steel is pulled through small round openings to create a rebar structure. While unfinished steel is the cheapest form of Rebar; however, sometimes epoxy-coated or stainless steel is also used. Epoxy-coated rebars are expensive as compared to other material rebar. After the steel has been properly shaped, it is twisted and grooved on the metal to ensure the stability of the structure. Their ends are protected with plastic caps to prevent accidental harm to workers. During construction, the rebars are bent through hydraulic benders and cutter on the basis of the requirements and sizes.

WHERE ARE WIRE MESH AND REBAR USED?

Wire mesh and Rebar are commonly used for a myriad of industrial uses. Wire mesh is widely used in industrial filtration, sieving, shielding, sorting, sifting, screening and separation procedures. Woven mesh is a highly flexible and malleable material. It can be shaped to suit precise requirements and edged to fit any structure. Wire Mesh is often used in industrial applications when separation and filtration is required. It is used in commercial applications like insect screening or animal fencing. They also provide various type of security, like in window machines, stairwell panel guards, fireplace screens, ventilation, RFI shielding, etc.

On the other hand, Rebar is used to provide resistance to support design loads. They are used for durability and aesthetic purposes, as well. They are commonly used in floor slabs, stairs, and roof construction. A heavier fabrication of welded wire fabric can be used in walls and structural floor slabs. This is commonly used in road pavement, box culverts, drainage structures, and small concrete canals.

Sunflag Steel offers a wide range of wire mesh and rebar products designed to cater to standard industrial processes and regular work. We can develop custom solutions to meet your unique requirements, as well. Please connect to us anytime for the perfect products for your needs.