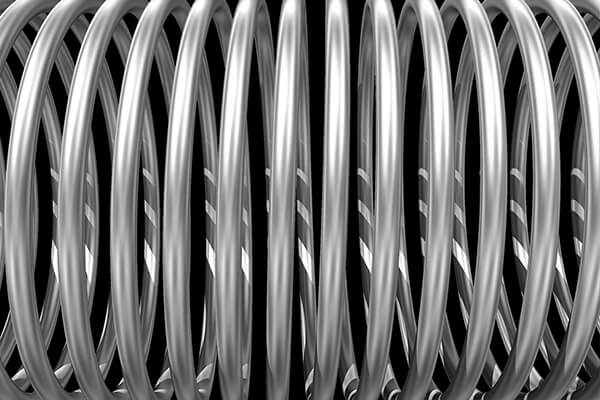

Spring steel is popularly referred to as an annealed spring steel and “general use” steel. Spring steel is generally classified in different categories such as a low alloy, medium carbon steel or high carbon steel with a very high yield strength. Spring steel has certain properties such as it is resistant to water, environmental and pollution exposure. Stainless spring steel can essentially come under two types which is either austenitic or martensitic. The austenitic stainless spring steel strips like 301 and 302 are temper rolled for light springs versus the martensitic spring steels, such as the 420 stainless strips, that are heat treatable for high hardness and toughness and are typically used for hardened tools.

Spring steel has many applications and uses attached to it. It also has many unique properties attached to it. For example, spring steel is said to have high yielding strength and also known to be resilient. Moreover, it also has the capacity to be formed, shaped and post heat treated. It is in fact these physical characteristics that make spring steel a general use steel. Since spring steel is essentially general use steel, it has a varied amount of commercial applications. Therefore, with its common material and its properties, spring steel is used to manufacture objects such as washers, lick picks, scrapers, saw blades, springs and antennas.

One of the common uses for spring steel is that it is used to create lawn mower parts, vehicle coil springs and tubular spring is used for the landing gear of small aircrafts as it has the ability to absorb the impact of landing. Another common usage of spring steel is that they are used as piano wires, such as ASTM A228. One popular use of spring steel is that it is used for the manufacturing of metal sword which are used for stage combat due to its resistance to bending, snapping or shattering. It is also used in the fabrication of lockpicks due to its flexibility and resilience. Spring steel is also utilized in making knives, especially for the Nepalese kukri and also used to binder clips. It is also extensively used in the making of shims as it possesses the resistance to deformation in low thicknesses.

Therefore, this piece highlighted the various properties attached to spring steel and also discussed many of its applications and usages.

BIBLIOGRAPHY

https://www.meadmetals.com/blog/common-uses-for-spring-steel

https://www.engineersedge.com/materials/spring-steel.htm

https://www.acxesspring.com/properties-of-common-spring-materials-spring-wires.html

https://www.precisionsteel.com/spring-steel

https://marketing.hardwareproducts.com/blog/classes-of-spring-steel-used-in-spring-manufacturing

http://www.nevatiasteel.com/know-significant-uses-spring-wire-various-application/